Visual Inspection

Visual Inspection

Visual Inspection is one of the most common methods of non-destructive testing. Visual Inspection requires training & Certification (for example, knowledge of product and process, anticipated service conditions and acceptance criteria)

Defects found by other NDT methods are ultimately substantiated by visual inspection. VT can be classified as direct visual testing and remote visual testing. The most common NDT methods, MT and PT, are simply scientific ways of enhancing the visual examination.

Remote Visual testing is more sophisticated, fiber-optic (Borescope) equipment allows the introduction of a device into very small access holes or channels. Most of these systems provide for permanent recording of the inspection. Cameras are indispensable for visual examination as a method of documentation.

Clarity Inspection can provide visual inspections that meet the code requirements of piping Vessel construction as well as offer in-service inspection of these items in the field.

API 510-Pressure Vessel Inspection & Exchanger inspection.

API 570-Pressure Piping Inspection

API 653- Above Ground Storage Tank Inspection

Please ask to review our ASME, CSA & API inspection Procedures!

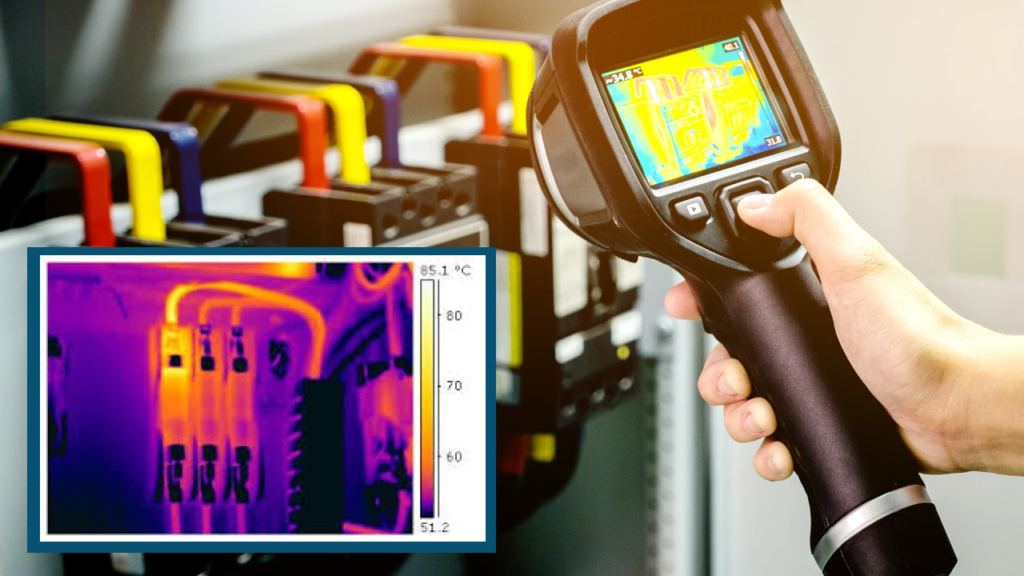

Thermography (IR) Infrared Testing

Infrared thermography is the process of using a thermal imager to detect infrared radiation (heat) that is emitted by an object. The technology allows operators to validate normal operations and, more importantly, locate thermal anomalies (abnormal patterns of heat invisible to the eye) which indicate possible faults, defects or inefficiencies within a system or machine asset.

A few examples of where infrared is applied in industrial situations include:

- Electrical Systems (faulty electrical connections or overloaded circuits)

- Mechanical Equipment (abnormally warm motors or possible bearing failures)

- Fluid Systems (line blockages, tank levels or pipe temperatures)

- Building Applications (detect missing insulation, air infiltration or moisture damage)

- Low-Slope Roofs (locate wet roof insulation)

Thermal-infrared inspections allow for the predictive maintenance of electrical and mechanical targets and can also be used for gas detection. Inspections can be performed quickly, accurately and safely, enabling the detection of problems prior to failure.

Leak Testing

Clarity inspection has Advanced procedures & equipment to perform Leak testing both the direct pressure bubble method as well as the Vacuum-box bubble leak testing method.

-Third party Hydrotesting & Surveilance Inspection.

(Leak Testing procedure available upon request)

Mobile Equiptment Testing

Annual inspection & certification of :

- Scizzor Lifts

- AWP’S

- Overhead Cranes

- Mobile truck Mounted Articulating Cranes

- Side Boom & Spreader Bar Certification.