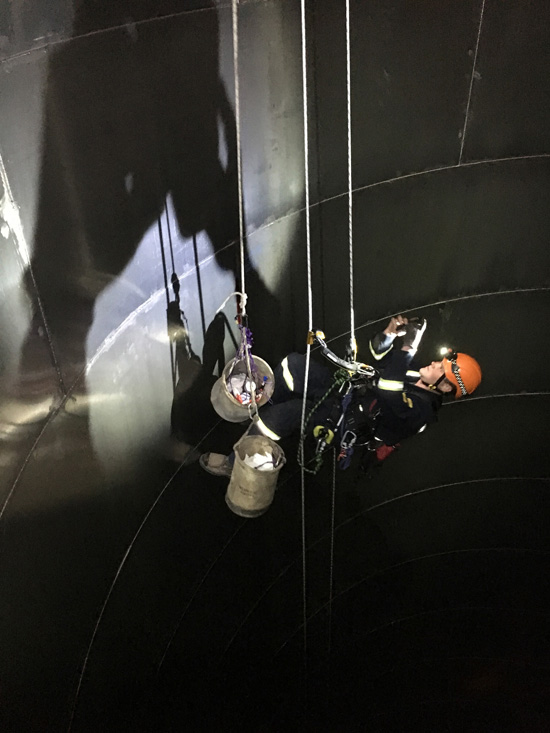

Rope Access Services

Clarity’s Rope access division can perform a wide array of tasks from integrity port installation to tradesmen support on remote access areas of your facility/ plant. Clarity enjoys supporting other companies whenever they need to get a job done in a tough spot in a safe & timely manor. The Rope access services that Clarity Inspection can perform but are not limited to are:

Rope Access Solutions

- Non-Destructive Testing (UT, Computed & Conventional Radiography, MT, PT, PMI)

- Integrity port installation on vessels & Piping circuits

- Insulation stripping & replacement.

- Insulation deficiency inspection & documenting.

- Pipefitting, Steam & glycol trace repair/replacement.

- Structural & Building Inspection, Ice removal, exterior repairs, window cleaning & caulking,

- Painting & Coating Inspection

- Lifting Equipment Inspection

- Internal & External Vessel Inspection.

- Bridge inspection

- Certified rope access welding services and trades work (ABSA B-Pressure / CWB)

- Electrical & instrumentation cable pulls, Sensor replacement, Fan motor changeouts.

- Advanced internal access solution for spherical vessels & HLS. (Internal adjustable boom c/w with power chain-hoist for time-efficient work positioning)

Key Benefits

The majority of access systems can be designed and rigged within a few hours. This allowing the necessary work to commence at an expedited rate.

In addition to its exemplary safety record, some of the advantages associated with industrial rope access when compared to conventional methods of access include:

Reduced Security Risk

Unlike other bulky and cumbersome access methods, rope access systems are dismantled and removed at the end of each working day, causing no disruption to work site operations, pedestrians near building projects and traffic flow. There is no risk associated with unattended ladders, scaffolds or other access equipment and materials.

Dramatically reduced time-related charges

Rope access systems require minimal installation and dismantling time. A full set of Rope access gear weighs only 15kgs and can be set-up or dismantled within an hour, while conventional methods of accessing, such as scaffolding, often require lengthy and expensive installation periods. This is mostly due to man hours.

No mechanical damage to protective coatings

Rope access activities do not cause any mechanical damage to the coatings of inspected structures. In comparison, the erection and dismantling of scaffolding usually results in damaged paintwork at contact points.

Significant reduction in labour cost

Studies have shown that the cost of performing visual inspection and Non-Destructive Testing by rope access can be drastically lowered (by up to 90%), when compared to the cost of access by traditional scaffolding.

For a site visit or virtual consultation, please contact us !.